Welcome to the

Printum Technology GmbH

Converting Solutions

We connect materials, processes and production equipment.

Web-Handling or Web-Converting is the process in which flexible materials such as paper, film, non-woven or membrane material are processed. At Printum, we call this ‘rotative manufacturing’. As a special machine builder, we start where the standard on the market reaches its limits. As an experienced engineering partner, we take a holistic approach to our projects – from the competitive industrialisability of the product to optimal factory planning.

Based on our customers’ requirements, we create pre-engineering concepts, feasibility studies and production concepts, carry out PoCs (proof of concepts) and realise engineering projects for various applications in different industries. We adapt the degree of automation to the product mix and the planned output quantity. If required, we combine rotative processes with pick & place.

Our modular design enables quick format changes and the production of variants. Clear structures separate the production, supply and drive areas. The open design allows options to be added at a later date. Advanced automation technology combined with highly sensitive components ensure precise web guiding. Our customers appreciate the intuitive and consistent operating concept.

Therefore we are your engineering partner.

Our know-how

Cutting

Die-Cutting

Coating

Testing

Laminating

Calendering

Drying

Cutting

Punching

Coating

Testing

Laminating

Calendering

Drying

Reference projects

Special machines for

Web-Handling & Converting

Project 01

Roll-to-Roll

Testing and inspection system

- Project 02 -

Roll-to-roll

Production plant for

coffee capsule sealing rings

Production plant for coffee capsule sealing rings

Project 02

Roll-to-Roll

Production machine for

coffee capsule sealing rings

- Project 03 -

Roll-to-Piece

Production plant for

insect glue traps

Production plant for insect glue traps

Complete roll-to-piece system for glue trap production: This highly automated roll-to-piece system produces a wide variety of insect glue trap products. From the raw material to the end product packaged ready for sale in a tubular bag. Optionally with or without the application of pheromones.

Roll-to-piece complete system for glue trap production: A substrate film is unrolled, printed, continuously glued, covered with silicone paper, cut to size and provided with cut-outs for hanging. The result: a stack ready for sale.

Complete roll-to-piece system for glue trap production: This highly automated roll-to-piece system produces a wide variety of insect glue trap products. From the raw material to the end product packaged ready for sale in a tubular bag. Optionally with or without the application of pheromones.

Project 03

Roll-to-Piece

Production machine for

insect glue traps

Project 04

Roll-to-Roll

Digital finishing

in label the production

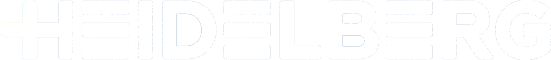

OEM cooperation: The unique DM-UNILINER 3D from Steinemann DPE (Kurz Company) enables digital transfer in web printing for an exceptionally appealing 3D label design with a metallic look and tactile relief printing: The substrates are decorated inline in a sophisticated way – Printum supplied the perfect web handling for this application.

Career

Apply now in under 2 minutes!

Apply now in under 2 minutes – without a cover letter or CV. Also easy via WhatsApp.

Are you a media technologist / printer (m/f/d) and already have valuable practical experience, for example in the label printing industry? …

You have completed an electrical engineering apprenticeship and have several years of experience as an industrial mechatronics technician, electronics technician or …

Have you completed a university degree or further training as a technician (m/f/d) in electrical engineering, mechatronics or robotics? …

Are you a committed team player with initiative? Are you a strong communicator, solution-oriented and motivated? Then apply today and become part of our team!

News

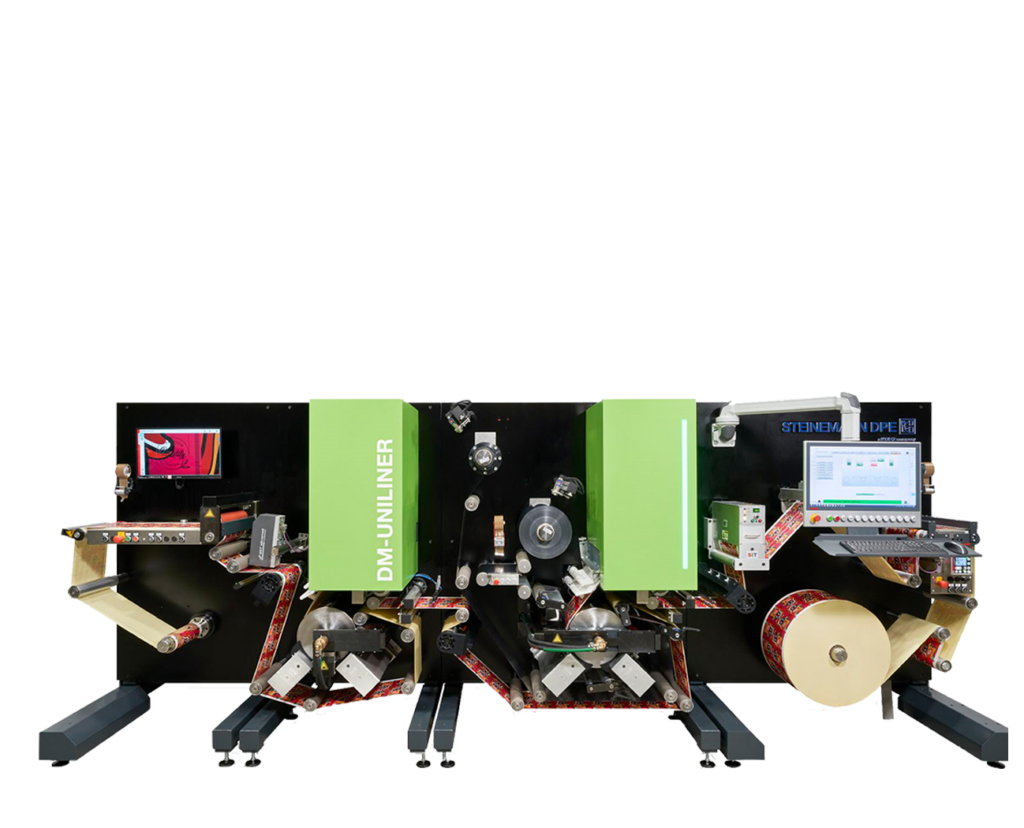

ICE Europe 2025, Munich

Together with our partner Partner Kocher + Beck we exhibited at ICE Europe 2025 in Munich.

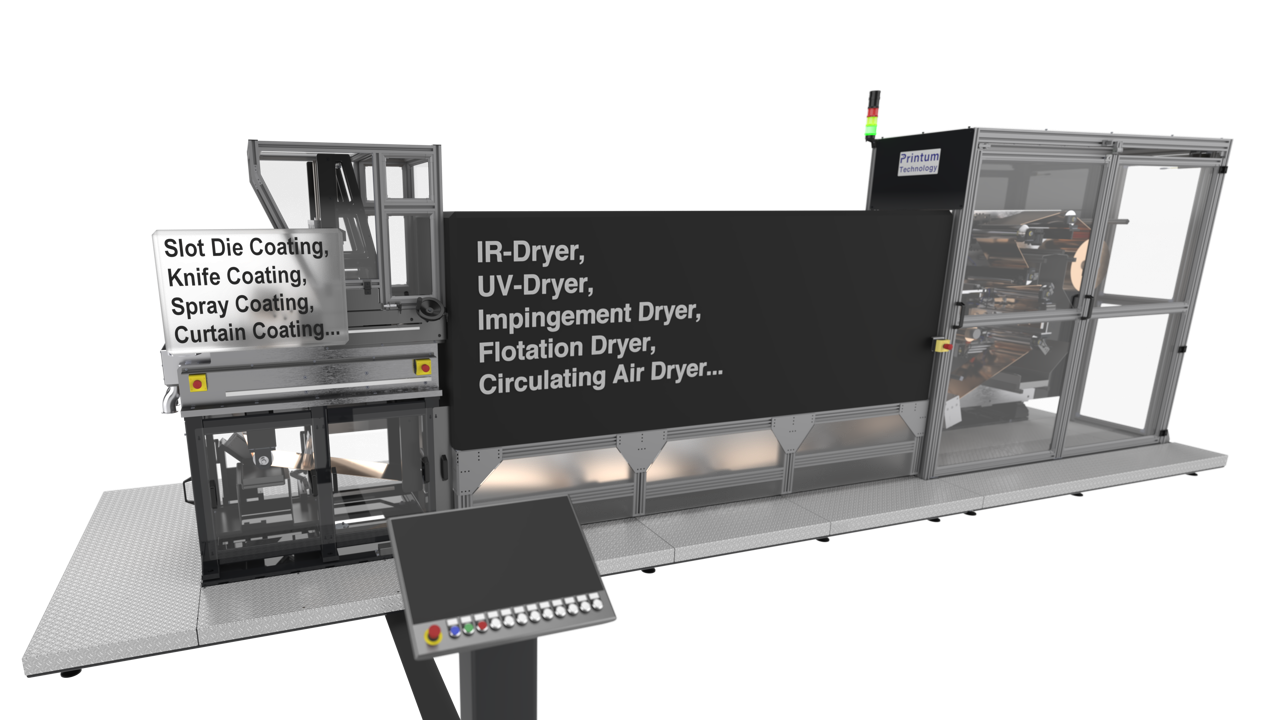

Product launch 2025: LOOP-COATER

The new loop coater integrates technologies for web coating and web drying – perfectly tailored to customer requirements.

New Location in Northern Germany

Together with our partner Kocher + Beck, we have opened an office location in Leopoldshöhe (Bielefeld).