Loop coater

Thin Film Technology (TFT)

Web coating

Loop coater

Test machine for high-volume products in web processing!

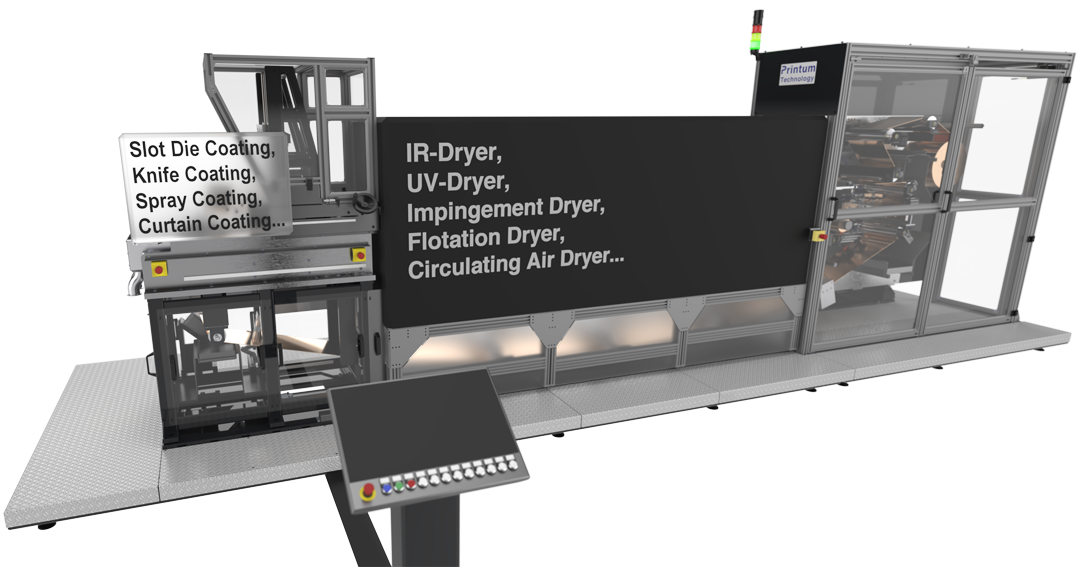

The concept is not new, but the special machine for it is… Introducing the Loop Coater.

Products such as battery cells, packaging etc. are produced in large quantities and accordingly at very high speeds of > 200 m/min. The ideal coating technology is central to the manufacture of these products. The interaction and dependency between materials, processes and machine equipment is incredibly complex.

With the loop coater, we are providing an answer to the question of how products for the battery, solar, packaging, paper and tapes markets can be developed even more efficiently – i.e. faster and more cost-effectively.

The concept is not new, but the special machine for it is… Introducing the Loop Coater.

Products such as battery cells, packaging etc. are produced in large quantities and accordingly at very high speeds of > 200 m/min. The ideal coating technology is central to the manufacture of these products. The interaction and dependency between materials, processes and machine equipment is incredibly complex.

With the loop coater, we are providing an answer to the question of how products for the battery, solar, packaging, paper and tapes markets can be developed even more efficiently – i.e. faster and more cost-effectively.

Advantages

More efficient, more profitable.

- Faster product development parallel to production

➔ Time-to-market! - Process development and parameter determination at process speed

- For very thin metal foils, plastic foils and membrane materials

- More efficient iteration loops because they are faster and more cost-effective

- 1:1 transfer of processes and parameters to the production plant

➔ Fast scale-up! - Small space requirement with dimensions of around 6 x 2.5 meters (L/W)

Specifications

Technical details

- Space requirement of 6 x 2.5 meters (L/W)

- Speeds up to 500 m/min

- Individual web widths available

- Individual selection and integration of the required coating and drying technology

- Coating systems:

including Commabar System, Slot Die Coating, Knife, Spray or Curtain Coating - Drying systems:

including IR/UV, Impingement Dryer, Flotation or Circulating Air Dryer – also in combinations

Application

Check diaphragms

High-precision coating testing for complex membrane products from the roll

Coating test for membrane electrode unit from the roll

Fully automated inspection and cutting system for high-quality membrane technologies and PEM electrolyzers such as CCM (Catalyst Coated Membrane) or MEA (Membrane Electrode Assembly). For detecting and marking defects: Read more…

Contact

Are you looking for a booster for your product development?

We will be happy to answer your questions about the Loop Coater or other products from our range. Please contact us without obligation.

Contact

Are you looking for a booster for your product development?

We will be happy to answer your questions about the Loop Coater or other products from our range. Please contact us without obligation.

Andreas Weigel

Sales

Sebastian Büker

Sales

Contact form

Contact form

Please fill in all fields marked with * are marked.