Ravensburg, Germany, Sept. 1, 2023

The international hydrogen and fuel cell industries are currently experiencing an unprecedented boom. As the key to the energy transition in Europe, hydrogen offers the potential to make Europe independent of oil and gas. In this dynamic environment, Printum Technology presents its latest innovation: a fully automated inspection and cutting system for highly sensitive material webs and membrane technologies such as PEM, CCM, or MEA.

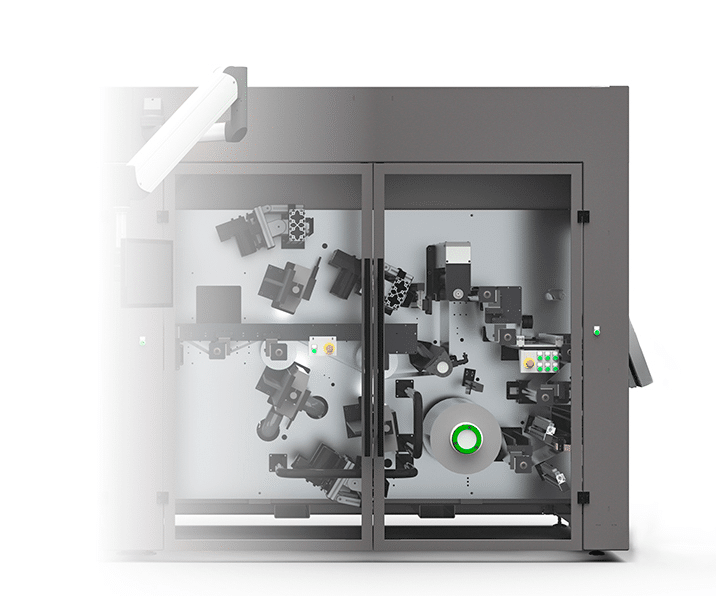

PEM Inspection And Cutting System

The system sets new standards for precise surface inspection and material testing. A high-resolution inspection camera and a marking system with laser and Inkjet printing unit are used to detect and mark defects. Other features such as low-friction swivel castors, web tension control as well as non-contact web speed and linear meter measurement ensure particularly gentle web handling of the high-quality membranes. It thus enables companies to validate test equipment for the production of cathodes and anodes, membranes and catalyst coatings, and to develop new quality standards. In this way, the special machine builder creates global competitive advantages for its customers.

The inspection and testing facility was designed for the industrialization of hydrogen technologies such as fuel cells. Since the system does not require a liner, significant resource and cost savings are possible in the commercial product development and production. In addition to fuel cell and battery manufacturers, the system can be used by automotive manufacturers and suppliers, the filtration and separation industry, as well as manufacturers of medical technology, energy and heating technology, who process ultra-thin membranes with particularly critical properties.

Read more about the new product ≫ here.

Previous milestone:

Back in November 2022, the Fraunhofer Institute for Solar Energy Systems ISE invited the Printum Technology team to Freiburg im Breisgau to present their initial successes and experiences with the market-proven lab-to-production approach. Since the system does not require a liner, significant resource and cost savings are possible in the commercial product development and production.

Read more about the past event ≫ here.

Upgrade for cutting membranes:

Using a sophisticated upgrade, the inspection system can also be used as a cutting line for highly sensitive material webs. This system can also be integrated into the production process. It combines all the advanced features and functions of its predecessor and adds a high-precision cutting function. After the inspection, it thus enables the conversion of the material webs for the subsequent processes. As a stand-alone membrane cutter, the major benefit is the resource-saving material processing without liners.

Read more about the new PEM converting and cutting line ≫ here.

Strategic advantages for manufacturers through differentiated use of equipment

Printum Technology understands the different needs of manufacturers and offers customized solutions for various areas of application. The PEM inspection system is ideally designed for companies looking to strengthen their internal research and product development. As a stand-alone solution operated offline and in parallel with main production, it enables companies to conduct their own in-house tests and thus become more independent. This promotes innovation and accelerates the market launch of new products

The PEM converting and cutting system, on the other hand, can be integrated directly into the production process to serve as an end-of-line solution. Precise converting based on the inspection system is possible . as a combined solution. This is a crucial step for companies on their way to establishing themselves as market leaders. With this equipment, manufacturers can ensure that only products of the highest quality leave the production site, thus gaining the trust of their customers and strengthening their market position.

Upcoming events

Now Printum Technology is pleased to announce that the company will be present at the Hy-fcell expo and conference in Stuttgart, Germany, September 12-13. Visitors are invited to visit Printum Technology and Kocher + Beck at booth C18 in Hall 4 to learn more about the latest innovations in custom machine building for hydrogen technology and fuel cell production.

Press Release Download

Download the press release about Printum Technology’s new product launch as a PDF file here: PEM inspection and cutting system for membrane technologies such as PEM, CCM, MEA, …