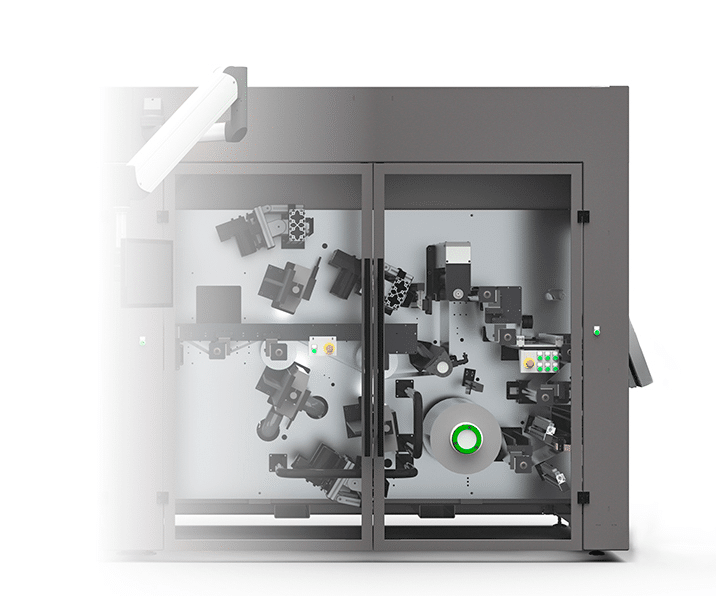

PEM-C520

CONVERTING SYSTEM

Membrane Cutter

Our fully automated converting and cutting line sets new standards for the precise splitting of parent rolls into smaller rolls and the cutting out of defective areas after material testing and surface inspection. Thanks to its particularly gentle web guiding, it is used, for example, as a membrane cutter for high-quality PEM products. Optionally, we also design systems for quality control.

With our market-proven solutions, you are gaining a competitive edge.

Features

Low-friction

Minimum inertia for lowest web tension: The system is characterized by minimal breakaway torques, low friction and acceleration ramps that are gentle on the material.

Web Width Measurment

As standard, the cutting width is determined with a high-precision line camera, which can also check the quality and precision of the cut.

Material testing and inspection

Various optional procedures for material testing and surface inspection ensure the quality of the end product.

Climate chamber

Since environmental influences such as humidity have a major impact on the materials, the system can also be built into a protective climate chamber.

Individual machine design thanks to placeholders

Placeholders let you integrate further optional inspection and testing methods, such as X-RAY sensor technology and ultrasonic layer thickness measurement. The specific design of the system to the materials to be processed, individual functions on the HMI and interfaces to various customer systems (e.g. MES).

Web tension control

All controllers and components are designed for lowest web tension. The parallelism of the rolls is optically measured.

Precise winding is ensured even with the lowest web tension via web center control of the unwinding and rewinding components. Sensitively programmed acceleration ramps round off the system.

Web control

Web speed and running meters can be checked and compared via the leading axis, or contact-free via a laser sensor.

Markings can be recorded and further processed by the vision sensor after unwinding.

Individual machine design

The specific design of the system to the materials to be processed, individual functions on the HMI and interfaces to various customer systems (e.g. MES).

Areas of application

Our system is the ideal solution for growing companies and emerging market leaders who demand the highest standards of safety and quality for their PEM products.

Industries

Automotive industry

Fuel cell, battery

Energy and heating technology

Electrolyser, fuel cell

Medical technologies

Membrane processing

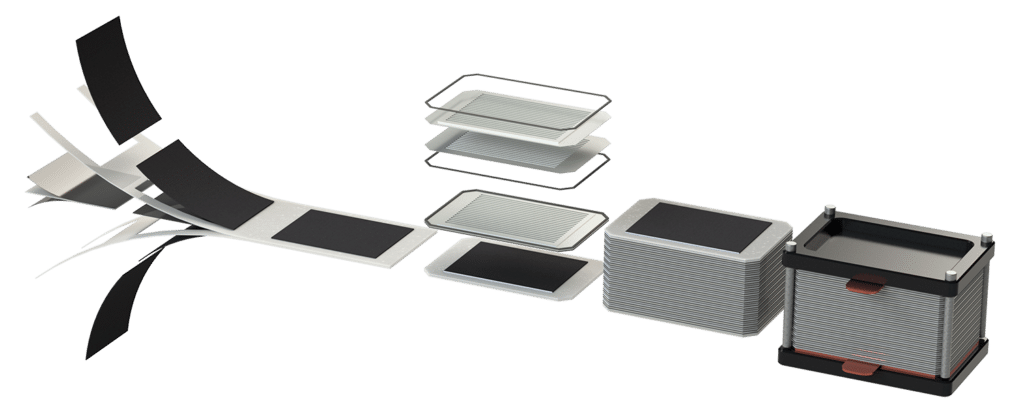

Products and components

- Membranes, films, and similar critical material webs

- Filter membranes in medical technology

- PEM, proton exchange membranes

- CCM, catalyst coated membranes

- KCD, cathodes

- ACD, anodes

Material properties

- highly sensitive

- extremely thin

- elastic

- easy to tear

- sensitive to scratches

- porous or brittle

- high-quality coatings

- partly multilayered

- climate-sensitive

Manufacturers and industries

Battery and fuel cell manufacturers, automotive industry as well as special machine builders (e.g. automotive suppliers), but also membrane processing in medical technology or the filtration and separation industry.

Products and components

Membranes, films, and similar critical or sensitive material webs, such as catalyst-coated proton exchange membranes for battery and fuel cell stacks.

Material properties

Highly sensitive, extremely thin and easy to tear, scratch-sensitive, porous or brittle, high-quality coating, climate-sensitive, in some cases also multi-layered.

Your Advantages

Market-proven

With our expertise as experts in handling highly sensitive materials, we are able to scale our market-proven technology to your requirements.

Mastering product quality

By precisely determining the web width and cutting quality, the end-of-line solution increases the quality of your end product.

Highest precision, exact results

Is the basis for precise cuts. And an ideal platform for cutting different materials and test methods.

Gentle on materials

By avoiding voltage peaks in the entire rewinding process.

Cost-cutting and eco-friendly

Since sensitive materials can also be handled and cut without liners, you reduce waste production and save costs.

Customized and flexible

Modular machine solution with placeholders for individual extensions and upgrades.

Download the product information sheet for the Printum inspection system.

Contact

Do you have questions or would you like to talk to our experts about your specific requirements? Contact us now.

Andreas Weigel

Managing Director

Sales

Please fill in all fields marked with *.