Special machines for web processing

We develop and build machines for all industries that process roll goods efficiently and to the highest quality. We either already have a solution ready or we can develop and build a customized machine for you.

Special machines for web processing for the development, testing and production of fuel cell components such as MEA, CMM and other electrolyzers.

Special machines for web processing in the development and production of lithium-ion batteries for the energy, electromobility and digitalization sectors.

Special application units for web processing in the production of flexible organic solar modules for a more sustainable future.

Special machines for web processing for the development, testing and production of fuel cell components such as MEA, CMM and other electrolyzers.

Special machines for web processing in the development and production of lithium-ion batteries for the energy, electromobility and digitalization sectors.

Special machines for web processing in the development and production of lithium-ion batteries for the energy, electromobility and digitalization sectors.

Special machines for web processing in the development and production of lithium-ion batteries for the energy, electromobility and digitalization sectors.

Special machines for web processing in the development and production of lithium-ion batteries for the energy, electromobility and digitalization sectors.

Special machines for web processing in the development and production of lithium-ion batteries for the energy, electromobility and digitalization sectors.

Special machines for web processing in the development and production of lithium-ion batteries for the energy, electromobility and digitalization sectors.

Home ➜ Industries & solutions

Industries & Solutions

Special machines for web processing

We develop and build machines for all industries that process roll goods efficiently and to the highest quality. We either already have a solution ready or we can develop and build a customized machine for you.

PEM hydrogen

Fuel cells and electrolyzers

PEM technology (proton exchange membrane) is used to generate hydrogen via electrolysis. PEM fuel cells convert hydrogen and oxygen into electrical energy and are used in the field of mobility and stationary energy supply.

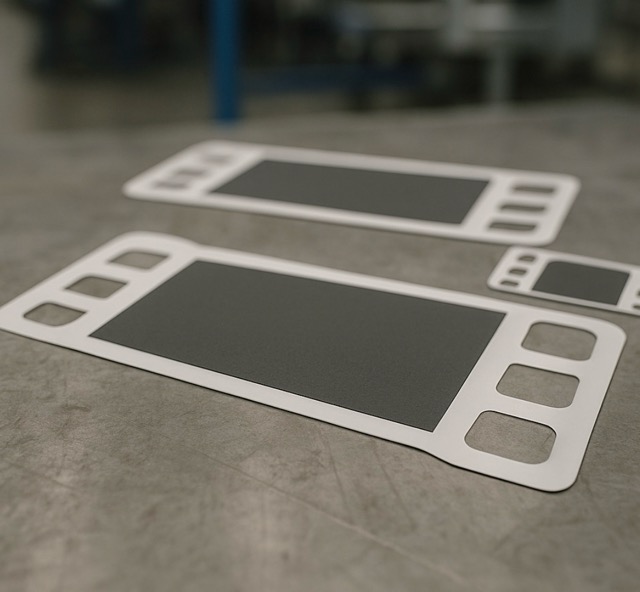

The membrane electrode assembly, also known as MEA, is the electrochemical heart of PEM fuel cells and PEM electrolyzers. All materials in an MEA come from a roll and are web-shaped materials.

MEAs are also used in: Solid oxide electrolyzers (SOEC), solid oxide fuel cells (SOFC), anion exchange membrane (AEM) electrolyzers and fuel cells, direct methanol fuel cells (DMFC).

Our solutions: Rotary production of the membrane-electrode unit with varying degrees of automation by combining rotary processes and pick & place, inline inspection of catalyst-coated membranes (CCM), cutting of subgas kets, gas diffusion layers (GDL) and CCMs, retrofits and machine upgrades.

Battery

Lithium-ion and redox flow batteries

Battery technology plays a key role for the future, particularly in the areas of energy, mobility and digitalization. The following processes take place in the production of lithium-ion batteries:

Coating with subsequent drying of copper or aluminum strips, calendering to compact the coating, dividing the wide electrode strip (mother roll) into several strips (daughter rolls), separating the anode and cathode electrodes from the daughter rolls, cutting the separator polymer film.

In redox flow batteries (RFB) and organic redox flow batteries (ORFB), a membrane is also at the heart of these systems.

Our solutions: Test and pilot machines for all manufacturing processes, loop coaters, machines for inline surface inspection during membrane production, cutting machines for particularly thin and porous membrane materials, retrofits and machine upgrades.

Flexible solar

Flexible, organic photovoltaics

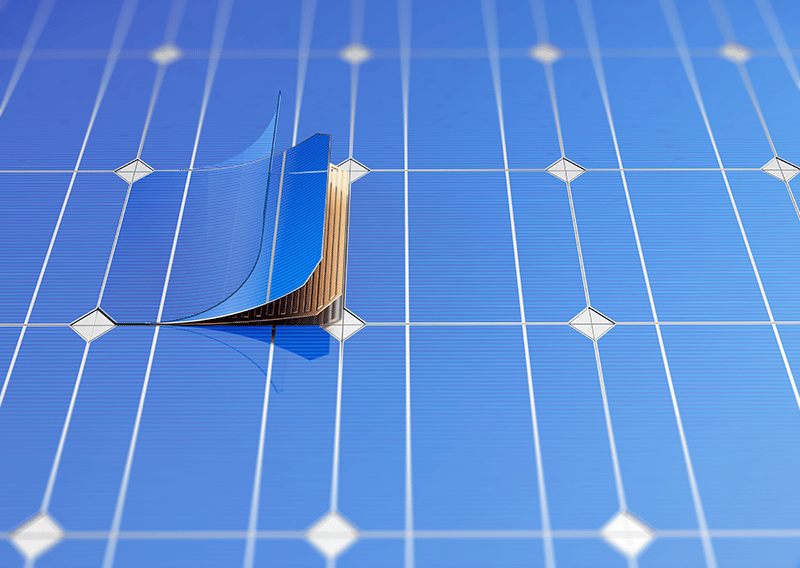

Organic solar cells, also known as organic photovoltaics (OPV), are solar cells made from organic materials such as polymers. Production in a roll-to-roll process is a cost-effective key technology.

Flexible solar cells are based on the same functional principle as crystalline photovoltaic modules. By absorbing light, a semiconductor changes from a non-conductive to a conductive state.

The following web-processing processes take place in the production of organic solar cells: Application of several thin layers on a carrier film, encapsulation process to protect the organic layer, application of contacts.

Our solutions: Test and pilot machines for all manufacturing processes, cross-web applicators for integration into systems to apply adhesive tape, contact tape and cosmetic tape across the web, retrofits and machine upgrades.

Flexible packaging

Web processing in the packaging industry

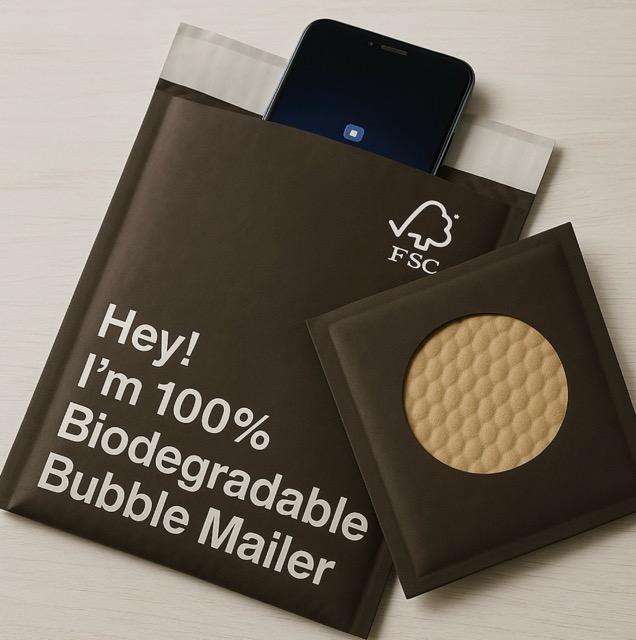

Web processing is a key element of the packaging industry because it enables high productivity, consistent quality and the flexible processing of a wide range of materials. Without it, many modern packaging solutions would hardly be economically or technically feasible.

This involves the further processing of web-shaped materials such as films, paper, cardboard, laminates or non-woven materials into products such as barrier packaging, protective mailing bags, pointed bags, gusseted bags, cross-bottom bags and block bottom bags.

Our solutions: Fully automated production lines for recyclable and padded e-commerce mailing bags, machines for the production of special packaging, automation of roll handling and the further processing of individual parts, retrofits and machine upgrades.

Label Converting

Our roots in label production

We originally come from the field of label printing and label converting. Since the end of the 1990s, we have been developing and building high-quality, customized converting machines for the label industry.

In the label industry, web processing is a central component of production. Labels are made from web-shaped materials such as paper and plastic films. The core processes here are: laminating, printing, coating, die-cutting and slitting. To date, we have focused on machines for the production of multi-layer labels such as sandwich labels or peel-off labels.

Our solutions: Multiweb machines, booklet machines, special machines for the production of special technical labels, laminating stations, multilayer kits, web offset devices, retrofits and machine upgrades.

Tape Converting

Self-adhesive technology from the railroad

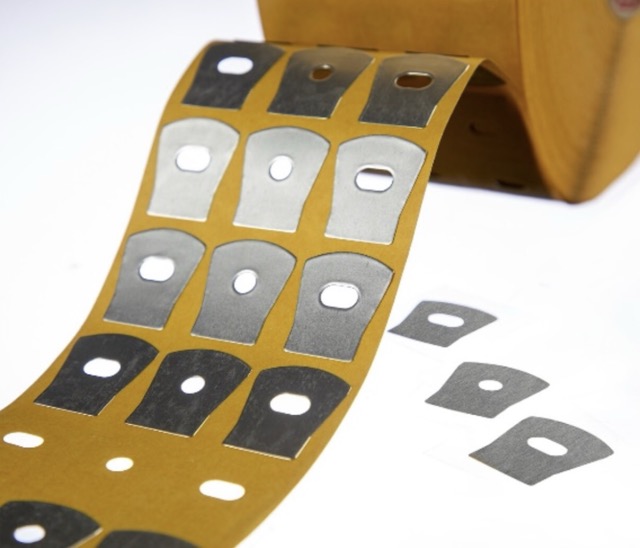

The tape converting industry is a specialized area of the manufacturing industry that deals with the further processing (converting) of adhesive tapes. Raw materials (e.g. from 3M, tesa, Lohmann, Nitto), i.e. large jumbo rolls of industrial adhesive tapes, are cut, punched, laminated or otherwise adapted into customer-specific shapes, sizes and formats.

Standard adhesive tapes often do not meet the exact requirements of industrial processes. The Tape Converter turns a standard product into tailor-made molded and die-cut parts for industries such as automotive, electronics, medical technology, aerospace, construction and household goods. From sealing tapes, surface protection films, static and dynamic seals, fastening systems to heat dissipation elements for battery production.

Our solutions: Customized and highly flexible tape converting machines, automation solutions for roll handling and single part handling, special components such as the microporous turner bars for guiding webs with open adhesive, retrofits and machine upgrades.

Filtration

Filter products from the roll

Filter elements are essential components for separating solids, liquids or gases. Web-shaped materials are always processed: Nonwovens, fabrics, paper, membranes and films. They are used in numerous industries and applications:

Engine air filters in the automotive industry, air filters for clean rooms in ventilation and air conditioning technology, filters for water treatment in environmental technology, sterile liquid filters for infusion systems in medical technology, ion exchanger filters and cathode filters in fuel cells, pressure compensation elements (PCE) in the electronics sector.

Our solutions: Test and pilot machines for all manufacturing processes, machines for inline surface inspection in filter production, cutting machines for particularly thin and porous materials, retrofits and machine upgrades.

Active ingredient patch

Converting processes in the pharmaceutical sector

Transdermal therapeutic systems (TTS, TDS), also known as active ingredient patches, are effective alternatives to taking medicines orally. The production of oral films, in which the active ingredient is absorbed via the oral mucosa, is also based on the same technology.

The web material is coated with the active ingredient, dried, laminated with the carrier film and then the products are punched out of the material web, checked inline and packaged. The precise uniform distribution of the active ingredient across the entire width of the web is crucial and must be measured precisely via the layer thickness. All machines in pharmaceutical and medical technology must be designed to conform to GMP.

Our solutions: Highly flexible test and pilot machines for testing and validating various application, drying and measuring systems, retrofits and machine upgrades.

Wound care

Sterile plasters, bandages and their packaging from cleanrooms

Web processing plays a central role in the production of wound care products, especially in the industrial production of large quantities. It is a continuous manufacturing process in which flexible materials (e.g. nonwovens, films, foams) are processed from the roll.

Products for acute and chronic wound care, such as plasters, sterile dressings, bandages, wound dressings, hydrogels or foam dressings, are manufactured under very controlled conditions. These products are individually packaged in clean rooms – often in airtight packaging that remains sterile. End-of-line sterilization processes, usually with steam, gamma radiation or ethylene oxide, are common.

Our solutions: Highly flexible test and pilot machines for testing and validating new products, retrofits and machine upgrades.

Non-Woven

Hygiene products in web processing

Web processing plays a central role in the area of hygiene nonwovens, as it has a significant influence on the quality, efficiency and functionality of the end products. Examples of hygiene products are Baby diapers, feminine hygiene products, incontinence products for adults, wet wipes and protective clothing for the medical sector.

Many of the hygiene products consist of an absorbent core/absorber, the top layer and a barrier layer.

Our solutions: Highly flexible test and pilot machines for testing and validating new products, special solutions, retrofits and machine upgrades.

Flexible electronics

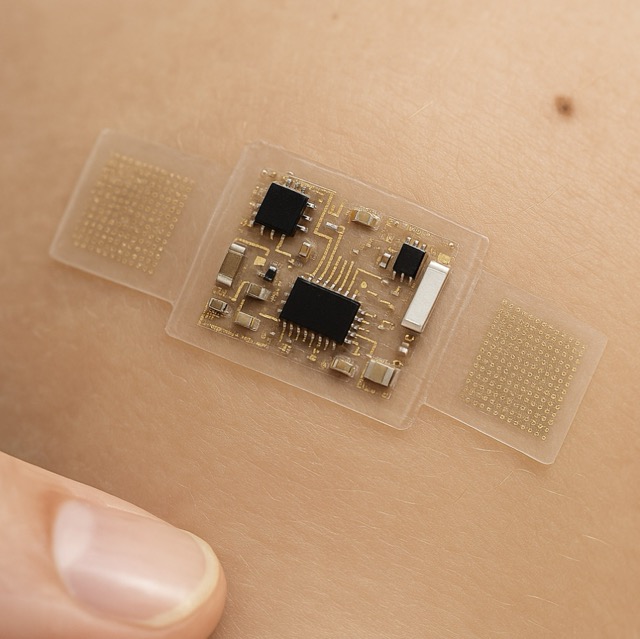

Wearable smart patches in web processing

Web processing is highly relevant for the industrial production of wearable smart patches, as it enables the integration of complex functionalities on flexible substrates while maintaining high efficiency and quality. It is particularly crucial for economic success in high-volume applications such as digital health monitoring.

The products contain sensors that are applied to the patient’s skin with an adhesive. They have electronics embedded in a foam to monitor the patient’s vital signs, such as pulse. They also monitor: neurological activity, glucose, pH values, muscle activity (EMG).

Due to the complexity of the products, they usually cannot be manufactured in a fully rotary process. Instead, rotary processes for separating the different materials and pick & place for assembling the individual parts must be combined in one machine concept.

Our solutions: Highly flexible test and pilot machines for testing and validating new products, retrofits and machine upgrades.